- Versions

- English Standard Version

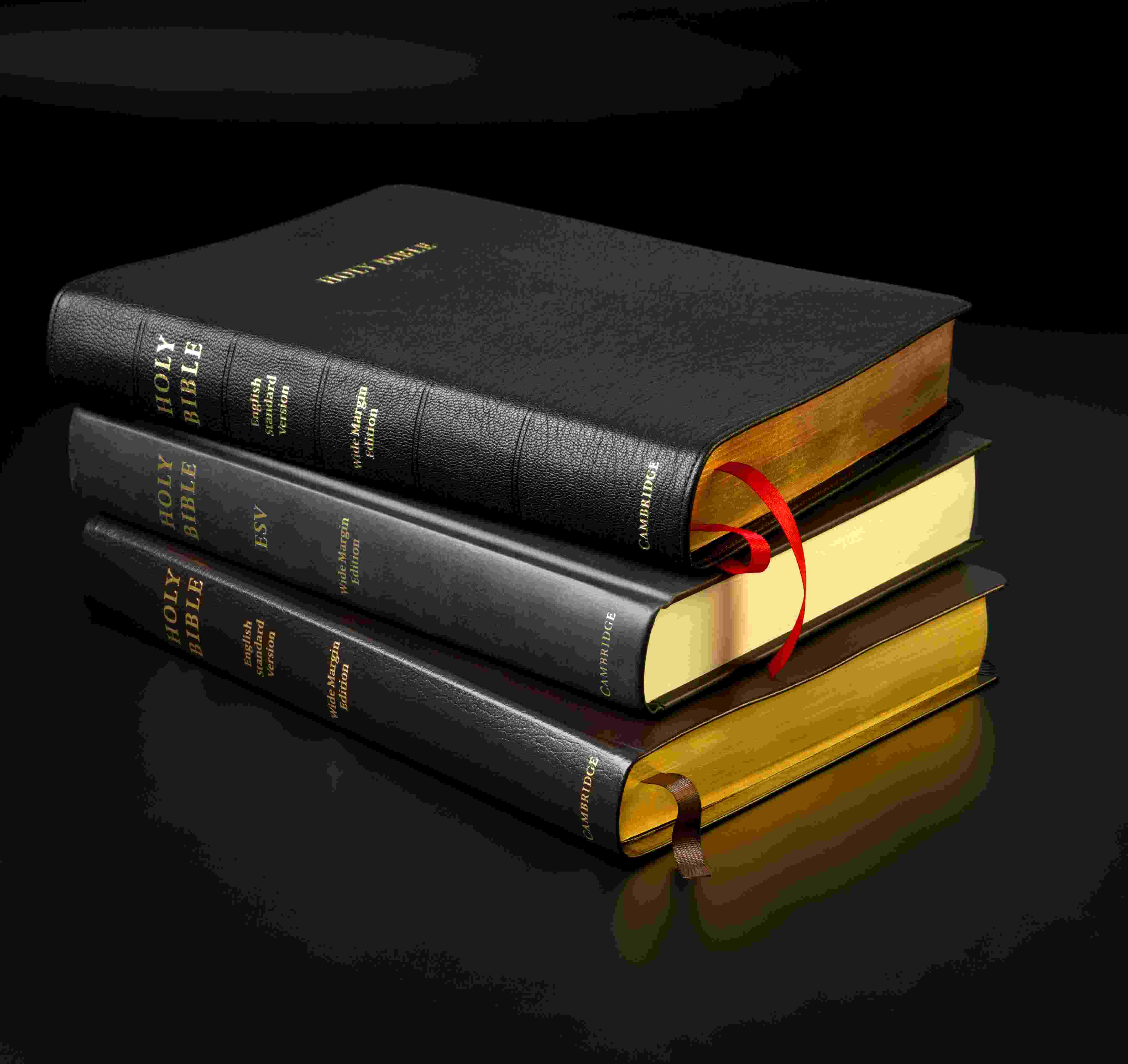

ESV Bible editions

- King James Version

- New English Bible

- New International Version

- New King James Version

- New Revised Standard Version

- Revised English Bible

- Revised Version

- Tyndale

- Original Greek

- Prayer Books

The quality of any Bible depends primarily on the materials and the processes used in manufacture, as well as on the more immediately apparent factors such as text design and layout. The following guide offers some pointers for prospective customers considering the purchase of a fine Bible.

Can you always judge a good book by its cover?

Not necessarily – first impressions may be misleading! Bibles come in a variety of cover styles and materials, but the range of options available for a particular edition almost always share a common printed book block – the pages inside the book’s cover – and the true measure of quality therefore begins with an assessment of the text design and the paper and print quality. One sometimes sees high-quality supple leather covers wrapped round an inferior book block, the quality of which is better suited to a basic and inexpensive mechanical binding style. Conversely, in the Cambridge list even the basic hardback Bibles have similar quality features – design, paper, print quality, sewn bindings – to the fine-bound styles of the same edition.

Consider the essential elements of the book, from the inside out …

Design

The Bible publisher’s first challenge has always been to present, within the covers of a single ‘book’, a large amount of text – more than three-quarters of a million words in the Old and New Testaments alone, equivalent to half a dozen or more novels. Traditionally this has been accomplished by printing on very thin paper using carefully chosen typefaces and type sizes, and cleverly designed page layouts. The printed page should be easy to read, but a small format Bible cannot be printed in a large typeface without increasing the number of pages and consequently the thickness of the book, so designers strive to find the optimum balance between readability and portability. The outer margins should be even, and in the centre of the book the ‘gutter’ margins should be sufficiently generous so as not to interfere with reading.

The Type

There are many variations in the styles and characteristics of typefaces or ‘fonts’ available to the designer. In order to be economical in the space it occupies and at the same time easy to read in small sizes, the font needs to be what was traditionally described as ‘large on the body’: the central part of the letter should be generously proportioned with modestly sized ascenders and descenders (e.g. the upward stroke of h and the downward stroke of p). A thin, spidery or condensed type may prove tiring to the eye, but one with over-thick strokes will make the page look too dark. Fussy or unusual letter forms may distract or irritate the reader.

Note that point size is not a universal measurement, nor is any specific point size in itself a guarantee of readability. Each font has its own characteristics, and an 8 point type in one font may well be considered just as legible as a 9 or 10 point in another. The amount of ‘leading’ between the lines, the length of the text line, and whether the text prints ‘line on line’ (see ‘Printing’) are all factors that may contribute significantly to readability.

The typefaces chosen for Cambridge Bibles have been selected to provide the most legible and attractive appearance for the particular style and size of each edition. Cambridge editions fall into two categories: traditional settings created in the days of hot-metal composition, and modern settings created using digital fonts selected to replicate the best characteristics of the familiar metal Bible typefaces. In effect, the older KJV settings such as the Concord, Pitt Minion, or Cameo Reference are ‘facsimiles’ of the original editions created many years ago.

Paper

Because of their length, Bibles have to be printed on very thin paper in order to achieve a suitably compact book. Nevertheless, irrespective of how thick or thin it is, paper in a Bible should have sufficient strength to sustain the usage it will receive. The best Bibles are printed on papers which are not only much thinner and finer than ordinary book papers, but which are also strong and have sufficient opacity to minimise ‘show-through’ from printing on the reverse side. Paper of 30gsm or less in weight – ‘20lb paper' in the US – is usually described as ‘India paper’ and over 30gsm as ‘Bible paper’.

Cambridge Bibles are printed on high-quality lightweight paper, chosen to achieve the optimum readability for the minimum bulk. Various factors – strength, thinness and opacity, and aesthetic qualities – are considered in sourcing appropriate papers that meet internationally recognised environmental standards.

Some Cambridge reference Bibles have wide margins, so that users can make notes against the Bible text. The paper used in these Bibles is chosen for its superior resilience and its capacity to absorb handwritten notes. Nevertheless, it is advisable to test pens and pencils on the paper before making extensive notes, to ensure that the ink flow is not so great as to bleed through the paper. Making notes in standard Bibles without wide margins is not recommended.

Printing

The appearance of the printed page is a good indication of the quality of both the printing and the paper. The position of the type on the page and the width of the margins should be consistent throughout. All letters should be sharp and clear and the inking should be even and uniform on all pages. In red-letter Bibles the register (the relative position of the red and black type on the page) should be accurate and consistent.

The best Bibles are designed to be printed ‘line on line’ (when one line exactly matches the position of a line of text on the reverse side of the paper) and have minimal show-through, even when printing on the thinnest papers.

Accuracy in printing fine Bibles is best achieved when the presses are run at slower speeds than is usual for mass-market Bibles or books, but this extra care inevitably has an implication for pricing. There are differences applicable to different Bible editions even within the Cambridge list, but generally Cambridge Bibles are printed on presses running more slowly and therefore more accurately, than the norm.

Another measure of printing quality is whether the pages are printed in the correct long-grain direction rather than cross-grain. As a simple test, run a finger along the inner margins of the book: if the pages are smooth to the touch, the book is printed long grain; if rough or crinkled, it is probably printed cross grain. Printing in the correct grain direction improves the ease with which the pages may be turned as well as their appearance, and also has an effect on the quality of the gilding. (The cross-grain edges of the book will appear wavy, and this effect is often highlighted by gilding).

In the Cambridge list, the older KJV settings such as the Concord or Cameo show text design at its classic best, albeit with some occasional minor blemishes in the print image (perhaps in individual character form) inherent in the process of converting typesettings created for letterpress printing into lithographic plates. Any such imperfections are a feature of ‘facsimile’ reproduction, and are not due to flawed page design or printing.

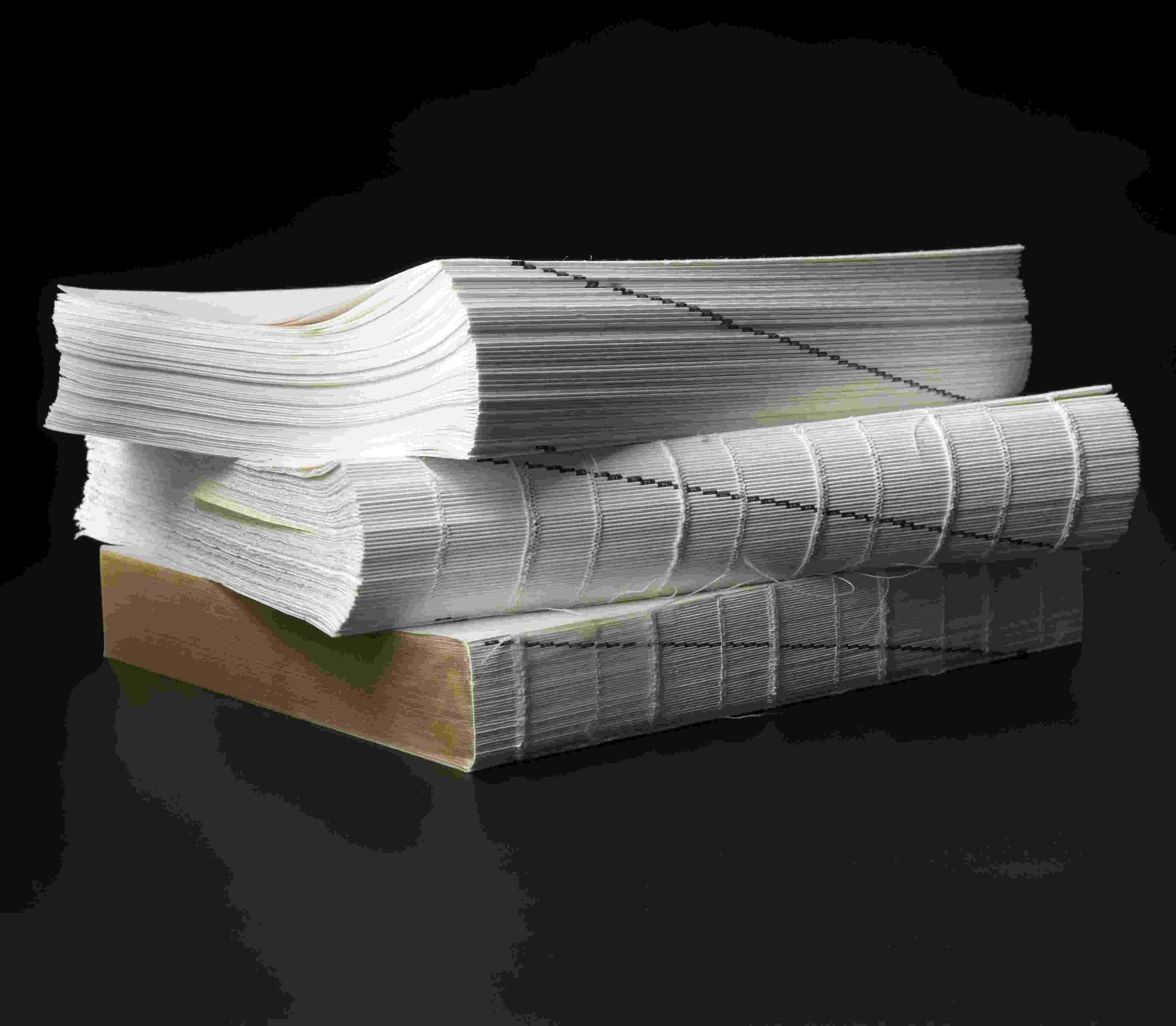

Sewing and Binding

To make a fine Bible demands more than skill in design and printing alone. If a Bible is to last and if its appearance and handling qualities are to satisfy, it must be bound in high quality materials with care and craftsmanship. Cambridge Bibles are always sewn (not merely glued as is often the case elsewhere). This adds strength and makes them last longer, and it also ensures the books lie flat once open. The thread used to sew the pages together is strong but thin, and so the reader should always open the pages carefully at first to allow the threads to settle. Of course, bending the cover back on itself is likely to over-strain the thread and may cause the binding to fail.

Note that all sewn books and Bibles are also glued. The sections are sewn together loosely, then nipped together and lightly glued along the spine (usually with gauze fabric attached) to hold the book block together properly. The glue penetrates a little between the individual sections, but the advantage of a sewn book is that the individual pages are not separately attached only by a single thin line of glue to the cover: each page is part of a folded section (a ‘signature’) of multiple pages; each signature is sewn to all the others; then all the signatures are glued to form a book block before being cased in to the cover.

Each style of bound Bible in a particular Cambridge edition will use the same basic sewn book block as one another; and so the less costly binding styles all offer the same quality of paper and standards of printing as the top-of-the-range fine bindings.

Attaching the case to the book block

There are two methods of casing in a fine Bible: the first (‘paste off’) is a semi-automated process of gluing the cover to the endpapers of the book block, while the second (‘edge-lined’) is a specialised handcraft process using a cover that is more flexible and that gives a firm attachment of cover to book. The hand-made edge-lined cover is attached to the book block by means of a flap (of about half an inch in width) of the inner cover material being glued to the endpapers of the book. Because these covers are hand-made, each Bible is in effect unique – no two will look exactly the same.

The cover – the final stage that creates the first impression

The cover material used in Bible binding not only affects one’s initial aesthetic response – both visual and tactile – but in the longer run also determines the durability of the book itself. The customer should balance these factors when considering a purchase. Except in Lectern Bibles or other bindings deliberately stiffened by the incorporation of a board between the outer cover and the lining, covers should be reasonably flexible, but at the same time should lie flat. The overlap protects the gilded edges. It should be of fairly uniform width all around the book, and the corners should be well rounded, smoothed down and firmly glued. The lining should adhere evenly all over the cover and be positioned so as to leave a uniform amount of the turned-in outer cover showing evenly. Often, a pattern or graining is artificially applied to leather during its manufacture but the best or most expensive flexible covers will usually feature the natural grain of the animal hide.

Cambridge Bibles use a range of leathers, with different grains appropriate to the size of each book. To maintain the fine quality for which Cambridge is renowned, the leather tanneries used by our bookbinders carefully select and scrutinise the best leathers from around the world. Of course, because leather is a natural product – however it is processed – each leather-bound Bible is unique; a facet that is particularly noticeable when natural-grain goatskin rather than an impressed leather hide is used.

Additional features and decoration of a ‘fine’ Bible

Gilt Edges and Blocking

Many Cambridge Bibles and Prayer Books are decorated on their covers and on the edges of their paper with metallic (usually gold- or silver-coloured) foil. The book block is trimmed, the edges are sanded, and the corners are evenly rounded, so that when the book is closed these page edges will show as a smooth gold or silver surface. The material used in this process gives a rich, bright, and attractive finish to the book. Some Bibles have ‘art-gilt’ edges, where a lustrous finish is created by a combination of red dye and gilt foil.

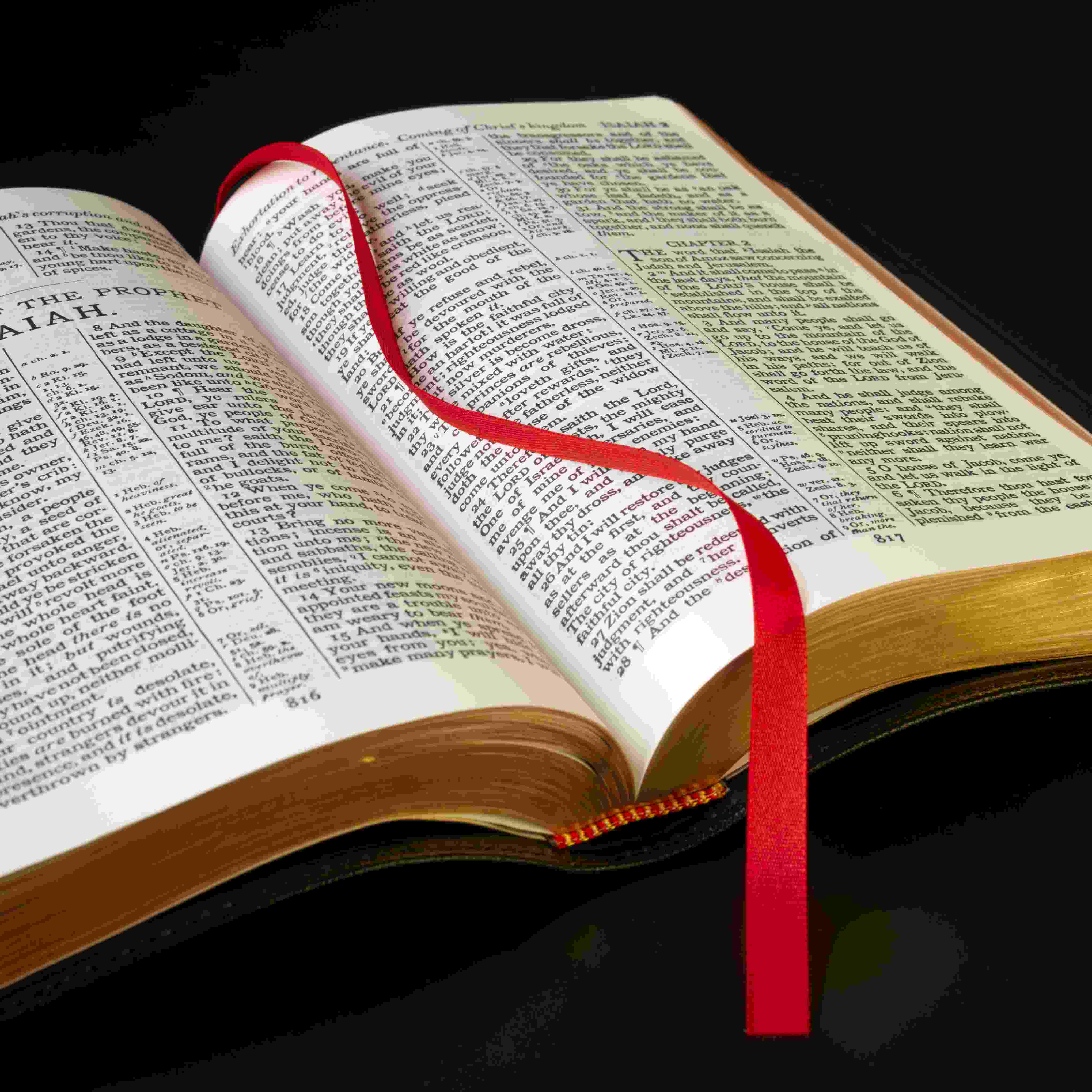

Ribbon markers

Ribbon markers allow readers to keep a place in the text while looking up cross-references, perhaps, or to mark a particular passage to which they will return. Care is taken in choosing ribbon markers for Cambridge Bibles. Strong ribbons of appropriate breadth for the size of each Bible are selected, so that they will not curl up, become thready or stringy or, in extreme cases, cut through the thin Bible pages. A generous length is specified, so that the ribbons do not get lost within the pages. If the Bible is one of the larger volumes or one of the top-of-the-range goatskin bindings it may have two ribbons, and the Lectern Bibles all have three, to allow easy marking of different readings.

Head and tail bands

Headbands appear at the top of the spine and tail bands at the bottom. Formerly, they were sewn onto the book block and protected the spine from damage when the Bible was taken from densely stocked bookshelves. Nowadays, they are added as a decorative item to all fine-bound Cambridge Bibles, as well as to many hardbacks, and the colours are chosen to complement the shade of material and gilding used in the binding.

Cover materials

Nowadays Cambridge Bibles may be bound in hardback or faux leather (bonded or imitation), or in various grades of real leather. The finest Bibles are bound in goatskin, a material used in traditional bookbinding for many centuries.

Real leather

Real leather is taken from an animal hide. ‘Split’ refers to the underside of the hide; the other side, ‘top-grain’, is superior and more expensive. When publishers use generic and imprecise descriptions such as ‘real leather’ or ‘genuine leather’, the Bible cover is usually made from an inferior and industrially produced split pigskin material.

Goatskin

A beautiful and very durable top-quality leather. Traditionally known as ‘Morocco’ leather, it is strong yet supple and is used in the finest bindings. The best goatskins for bookbinding come from arid areas where environmental conditions are ideal for producing hides with the necessary balance of strength and suppleness. Here they are partially tanned using the same traditional vegetable preservative materials and methods which have been used through many generations.

Calfskin

A traditional high-quality leather used in fine bindings. It is long-lasting and becomes more supple with use. The finest calfskin is renowned for its distinctive natural grain and rich colour shading, features that will contribute to the ‘uniqueness’ of each cover.

The best quality calfskin is sometimes known as ‘top grain’ in the US. This refers to the retention of the strongest part of the hide. Some Bible publishers use cheaper grades of thinner, split calfskin, which lack the subtle qualities of the best material but are otherwise similar in appearance. Properly, they should be identified as such by using a different name to distinguish a split from a top grain.

Calf split leather

A superior grade to French Morocco leather, tanned to approach the quality and feel of full-grain calfskin leather.

French Morocco leather

Slightly thinner than other grades of leather, and therefore relatively flexible and soft even when new. A French Morocco binding offers high-quality real leather at an economical price.

Cambridge uses this term for leather taken from a split hide, traditionally sheepskin but now often calf or cowhide.

Faux leather

Bonded leather

This may be made from a combination of materials: leather fibres and bonding resin and – with inferior grades – sometimes other ‘filler’ material such as card and paper. The materials used determine appearance and longevity: not all Bible bindings described as ‘bonded leather’ are of equal quality.

Cambridge Bibles with bonded leather covers use the best quality

- Accessibility

- Privacy & Legal

- Our Ethics

- Modern Slavery Statement

- Rights & Permissions

- Feedback

- Media

- Sitemap

- © Cambridge University Press 2024

- back to top

Are you sure you want to delete your account?

This cannot be undone.

Thank you for your feedback which will help us improve our service.

If you requested a response, we will make sure to get back to you shortly.

×Please fill in the required fields in your feedback submission.× - English Standard Version